About Us

About Us

“Established in 1994, Nav Durga Capacitor Company is a leading manufacturer and supplier of high-quality capacitors, providing reliable solutions to a wide range of industries. Established with a commitment to excellence, we have become a trusted name in the field of electrical components, known for our innovation, quality, and customer-centric approach.”

At Nav Durga Capacitors, we specialize in designing capacitors that are durable, energy-efficient, and capable of handling the evolving demands of modern technologies. Our state-of-the-art manufacturing facility, combined with rigorous quality control, ensures that every product leaving our plant meets the highest standards.

About Us

ND Capacitors is a leading manufacturer and supplier of premium-quality capacitors, committed to powering the future of electrical and electronic systems with innovation, precision, and reliability. With decades of expertise in the field, we have earned a strong reputation for delivering world-class products that meet the highest standards of quality, performance, and safety.

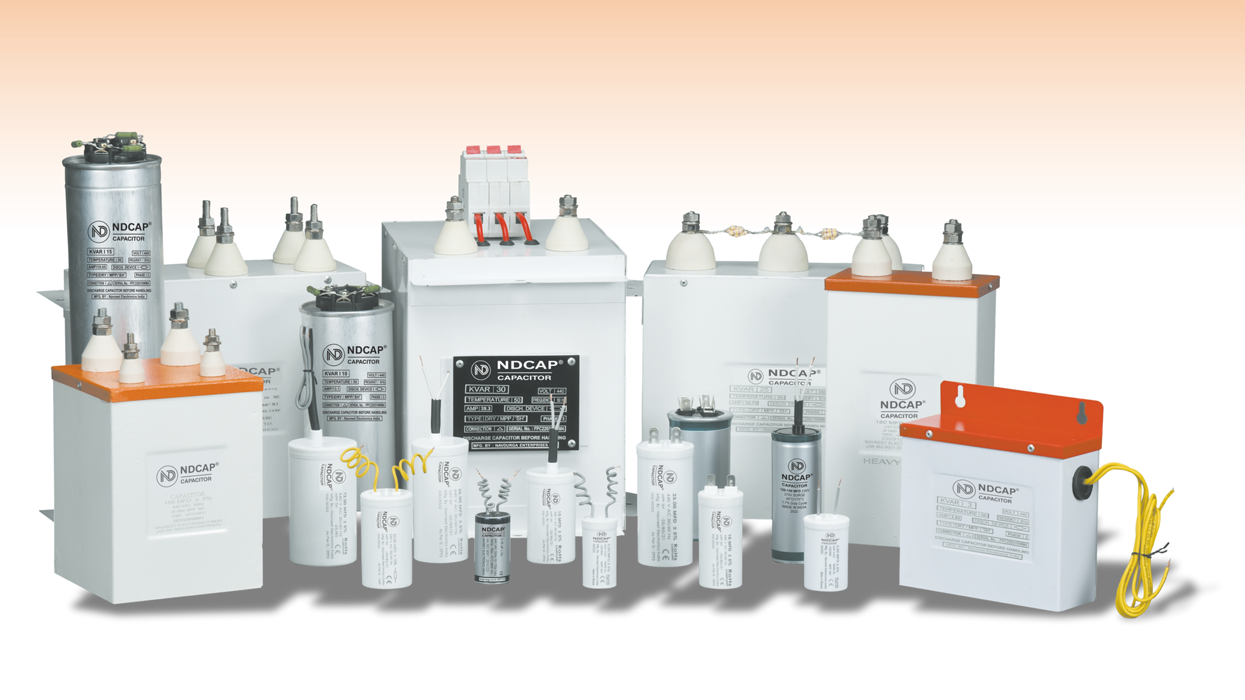

Our wide range of capacitors is engineered to serve diverse industries including automotive, consumer electronics, industrial machinery, renewable energy systems, HVAC, and more. From power factor correction to motor run and start applications, ND Capacitors offers robust, energy-efficient solutions tailored to meet the evolving needs of modern technology and infrastructure.

quality assurance

Our Company have a well trained & qualified technical team. They strive to meet company goals & customer ratification. The management of our company provides a transparent where every employee is encouraged to provide best products & services. The quality management systems at our company certified since 2004 in accordance with ISO 9001-2015 Quality Management of the organization is based upon quality procedures as laid out in accordance to Company quality manual, every Raw Material inspection with acceptable levels of quality. Only the acceptable material enters the stores after a systematics incoming inspection in our Company every capacitor is subjected to all requirements with a dedicated 100% Routine tests.

SELF HEALING

When a breakdown occurs at a week point in the dielectric, an arc is struck between two adjacent metal coating. The metal coating in the immediate vicinity of the puncture evaporates very quickly and, in doing so, extends the length of the arc. Both the impregnating agent and a tiny part of the dielectric also decompose in this arc, and a zone of high gas-pressure is formed, which forces the metal vapor away from the surface of the coating thus preventing condensation in the immediate vicinity of the puncture.

This rise in pressure and the rapid increase in the length of the arc cause fast de-ionization at the point of puncture. ensuring that the short-circuit current is generally interrupted within 5-10 microseconds irrespective of the amount of energy which is available. Apart from a small puncture no other damage occurs to the dielectric whatsoever, And owing to the metal-free zones which form in the immediate vicinity of the puncture. the insulation level of the dielectric of the capacitor is instantly restored to its full value. The capacitor then remains fully serviceable after one or even more such ‘self healings’

WINDING

Winding / Elements are produced in Air Conditioned, dust free humidity controlled winding room. These capacitors are manufactured out of trilayer Metallised polypropylene Film with heavy Reinforced Edges; to provide excellent bonding between the electrode and spray. Heavy edge has high current carrying capacity and with stands electromechanical stresses caused by switching surges better

TESTING LABORATORY

Testing facilities for conducting all routine test as per relevant BIS specification are available. We at FALCON capacitor has installed a fully automatic testing system / equipments to test capacitors up to 880 VAC between terminals, capacitance measurement and Tan-Delta all these tests are carried through automatic Instruments, there by eliminating human error and achieving ‘0’ defect product in addition, the following type tests are carried out at our works. Tests for capacitance measurement, sealing test, voltage test, visual examination, endurance test Etc.